Aircraft Piston Engine Vibration Isolation System

Aircraft Piston Engine Vibration Isolation System

Piston engines are common internal combustion engines used in small airplanes, drones, and some light helicopters. They generate power through the reciprocating motion of pistons. These engines produce explosions by burning a mixture of fuel and air, which propels the piston downwards. This motion is then converted into rotational motion of the crankshaft through a connecting rod. The rotational power of the crankshaft is transmitted to the propeller or thrust system, thereby propelling the aircraft forward.

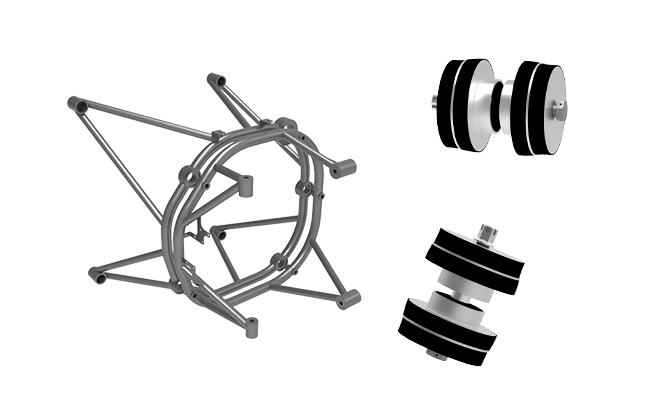

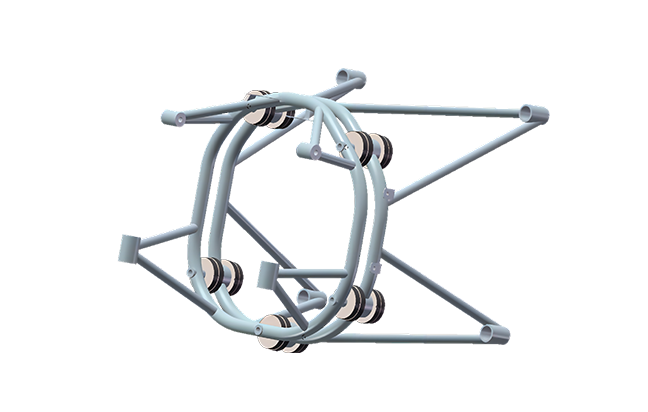

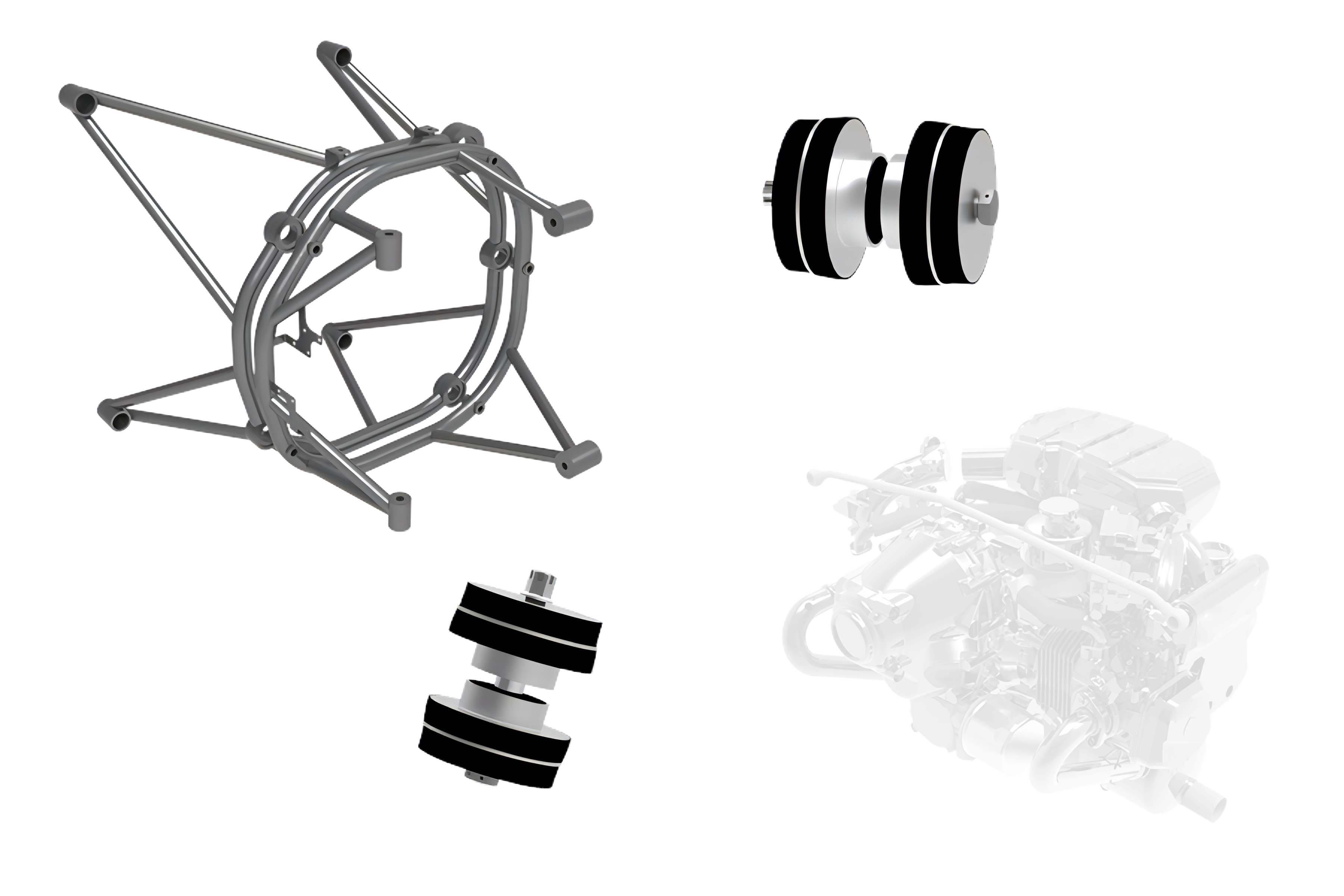

Due to the operational principles of piston engines, the reciprocating motion and explosive forces generate vibrations and oscillations. To reduce the transmission of these vibrations to the aircraft structure and passenger cabin, piston engines typically require vibration isolators. These isolators aim to improve the comfort of the aircraft, reduce fatigue damage, minimize discomfort for pilots and passengers, and mitigate the impact of vibrations on other aircraft systems and equipment, ensuring their normal operation.

The design and selection of aviation engine vibration isolators are based on specific requirements and performance parameters of the engine and aircraft. We possess independent development capabilities for domestically produced high-temperature vibration-reducing rubber materials and nonlinear elastic products, as well as extensive experience in the forward design and development of isolation systems. We have successfully implemented vibration isolation systems on multiple models of unmanned aerial vehicles. We will design and test the isolators according to the actual circumstances to ensure effective vibration reduction and provide excellent isolation performance during aircraft operation.